Oak Ridge National Laboratory, Department of Energy, developed a new polymer to bind and reinforce silica sand in binder jet additive manufacturing. This is a 3D printing method used in industries for prototyping or part production.

The printable polymer allows for sand structures with complex geometries and exceptional strength and is also water-soluble.

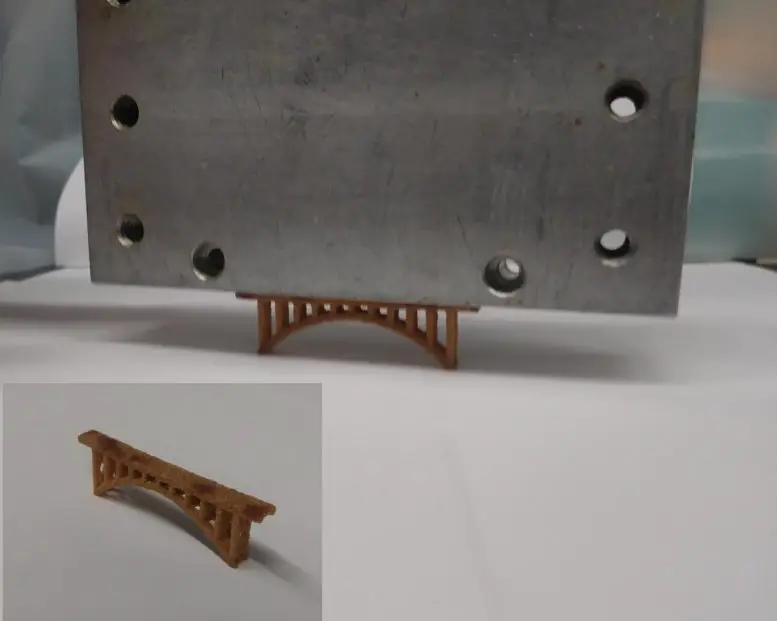

The study was published in Nature Communications. It shows that a 3D-printed, sand-print bridge can support 300 times its weight at 6.5 cm. This feat resembles the 12 Empire State Buildings on the Brooklyn Bridge.

Binder jet printing is faster and cheaper than traditional 3D-printing methods. It allows you to create 3D structures from various powdered materials. This gives you advantages in both cost and scalability. This concept is similar to inkjet printing except that the printer head uses a liquid polymer instead of ink to bind powdered materials like sand. It builds up a 3D design layer-by-layer. The binding polymer gives printed sand its strength.

This team utilized their polymer expertise to create a PEI binder, which doubled the strength and durability of sand parts compared to conventional binders.

Binder jetting parts are porous at first when they are removed from the printer bed. You can strengthen them by adding cyanoacrylate to the design. This fills in any gaps. The second step gave an eight-fold increase in strength over the first. This made the polymer sand composite more durable than any other building material, even masonry.

“This application requires a specific type of polymer. We sought out properties such as solubility that would yield the best results. “Our key finding was in our PEI binder’s unique molecular structure that makes it reactive to cyanoacrylate, which gives us exceptional strength,” stated Tomonori Saito from ORNL, the lead researcher.

While conventional binders can make parts denser by adding infiltrate materials like superglue, none of these have been able to match the performance of the PEI binding agent. The PEI binder is vital because it reacts with cyanoacrylate during curing.

The super-strength of sand could be used to develop tooling for composite manufacturing.

Silica sand, a readily available and cheap material, is used to create composite parts in the aerospace and automotive sectors. Lightweight materials like carbon fiber and fiberglass are wrapped around 3D-printed sand cores or “tools” and heat cured. Silica sand has two advantages: it is washable and does not shrink when heated. A water-soluble binder is essential for composite applications. It allows a simple washout with tap water to remove the silica sand and leaves a hollow hybrid form.

“A material that doesn’t change shape during tooling is essential to ensure precision. This is why silica has been so promising. Dustin Gilmer, a University of Tennessee Bredesen Center student who was the study’s lead writer, said it has been difficult to overcome structural weaknesses in sand parts.

The current sand-casting cores and molds are not suitable for industrial use. Commercial methods such as washout tooling apply heat and pressure to the sand, which can cause it to fail or break on the first attempt. More substantial parts will be needed for large-scale manufacturing and rapid part production.

Gilmer stated, “Our high-strength, polymer sand composite increases the complexity of parts that can be made using binder jetting methods. This allows for more complex geometries and broadens applications for manufacturing and tooling.

The industry partner ExOne licensed the novel binder for research and won a 2019 R&D 100 Award.