Imagine a small, autonomous vehicle that can drive on land, stop and then flatten into a quadcopter. The vehicle then flies away as the rotors spin. What do you see if you looked closer? What mechanisms transformed it from a vehicle on land into a quadcopter flying? It might be a combination of gears and belts or a series of tiny servomotors that put all the pieces together.

Michael Bartlett (assistant professor in mechanical engineering at Virginia Tech) would have created this mechanism, and you’d see a new method for shaping materials. The researchers used rubber, metal and temperature to mold materials and then fixed them using no motors or pulleys. The work of the team has been published in Science Robotics. The paper’s co-authors are graduate students Dohgyu Hwang and Edward J. Barron III and A. B. M. Tahidul Haque.

Getting into shape

Nature is full of organisms that can change their shape to fulfill different functions. The octopus transforms dramatically to move, eat and interact with its environment. Humans flex their muscles to support loads and keep their shape. Plants move to catch sunlight throughout the day. How can you make a material capable of performing these functions to create new types of multifunctional, morphing robotics?

Bartlett stated that when we began the project, we wanted a material capable of changing shape, holding that shape and returning to the original configuration. This could be done over multiple cycles. “One of the challenges was finding a material that could change its shape dramatically but also be strong enough to make machines that can do different functions.

The team used kirigami to create a structure that could easily be modified. This is the Japanese art of cutting paper into shapes. This method is different from origami which involves folding. The team created a material architecture that repeats a geometric pattern by studying the strength of the kirigami patterns found in rubbers and composites.

They needed a material that could hold its shape and be easily reshaped on demand. They created an endoskeleton from a low melting alloy (LMPA) embedded within a rubber skin. Normally, a metal will become bent, cracked or fixed if stretched too far. Researchers turned this common failure mechanism into a strength by embedding the special metal in rubber. This composite can be quickly stretched to the desired shape, making it ideal for soft morphing materials, which can instantly become load-bearing.

The material must return the structure to its original form. The team used soft heaters that resemble tendrils to heat the LMPA mesh. The heaters convert the metal to a liquid at 60 Celsius (140 Fahrenheit), which is 10 percent below the aluminum’s melting temperature. The elastomer skin holds the melted metal and pulls it back into its original form. This gives the composite what researchers call “reversible plasticity.”

These composites contain a metal endoskeleton embedded in rubber with gentle heat. The kirigami-inspired cuts create a variety of metal beams. This, combined with the unique properties and characteristics of the materials, made it possible to morph quickly, form, then return to its original shape.

Researchers discovered that the kirigami-inspired composite design could produce complex shapes. These could include cylinders, balls, and the bumpy bottom of peppers. The shape change can be done quickly. After impact with a ball, the shape changes and is fixed in less than a second. You can also repair the material multiple times by melting the endoskeleton of the metal.

One drone for air and land, one for the sea

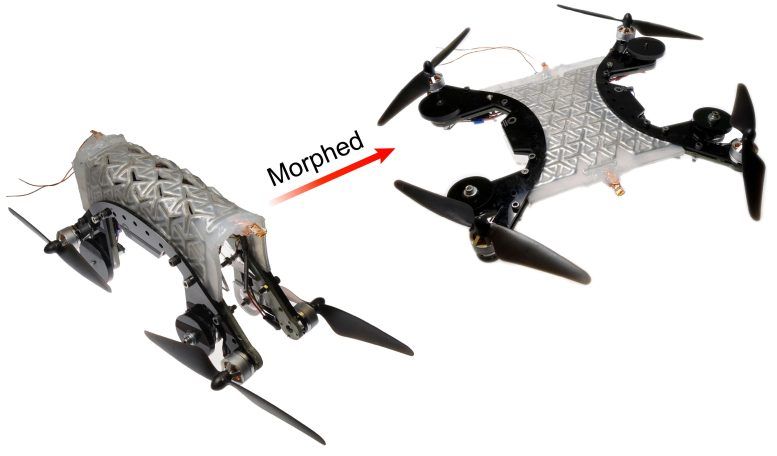

This technology has many applications. The team combined this material with motors, onboard power, control and motors to create a functional drone that can autonomously transform from a ground-to-air vehicle. The team also developed a small submarine. It uses the material’s morphing and return to retrieve items from an aquarium.

We are excited about the possibilities this material offers for multifunctional robots. Barron stated that these composites can withstand the forces of motors and propulsion systems but can easily shape and morph. This allows machines to adapt to their surroundings.

The researchers see the future role of morphing composites in soft robotics. They can create machines that perform different functions and self-heal when they are damaged. This will increase resilience and spark new ideas for human-machine interfaces.